-40%

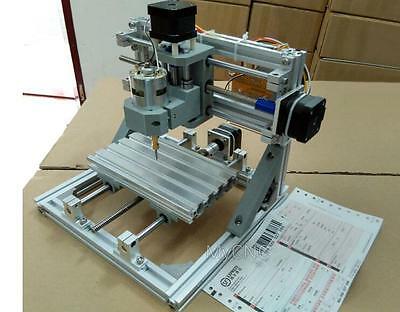

CNC ROUTER ENGRAVER MACHINE ENGRAVING DRILLING 3 AXIS 6040 USB 1.5KW VFD W/RC

$ 498.96

- Description

- Size Guide

Description

CNC engraving machine parameters: X, Y, Z Working Area: 600(Y)*390(X)*120(Z)mm Outside dimension: 865*680*570mm(L*W*H) Table size: 770(Y)*490(X)mm Lathe structure: 6061/6063 Aluminium alloy Max. Feeding height: ≤100mm Drive unit: X axis---1605 Ball Screws Y axis---1605 Ball Screws Z axis---1204 Ball Screws Sliding unit: X axis---High intensity Chromeplate shaft Y axis---High intensity Chromeplate shaft Z axis---High intensity Chromeplate shaft Stepping motor: 57 two-phase 3A 150N.cm Spindle motor: (tips:1. The spindle motor must connect with the VFD. 2. It cannot directly connect with the supply voltage (AC220V). 3. Please don’t change the data setting of the VFD if you are not professional technicians, or it might damage the spindle motor. Outside dimensionStore category

Sign Up Now !

You may also like

CNC ROUTER ENGRAVER MACHINE ENGRAVING DRILLING 3 AXIS 6040 USB 1.5KW VFD W/RC

Product Description

Not shipping country

canarias

Brand

Unbranded/Generic

MPN

Does not apply

Model

6040

UPC

Does not apply

EAN

747180862560

X, Y, Z Working Area

600(Y)*390(X)*120(Z)mm

Outside dimension

865*680*570mm(L*W*H)

Table size

770(Y)*490(X)mm

Lathe structure

6061/6063 Aluminium alloy

Max. Feeding height

≤100mm

Cooling

Water-cooling

Carving Instructions

G code / TAB files / nc file / NCC files

Communication interface

through parallel connection with computer

Software environment

Windows XP/Win7, 32bits system

Carving speed

0-2500mm/min(different materials differ)

Bundle Listing

Yes

ATTENTION : This machine comes with EU plug , please prepare an UK adapter plug cable yourself

IF YOU HAVE ANY QUESTION, PLZ CONTACT US!

SKU: 3AIX60401+3AIX60403+3AIX60404+TS007

Attention:

This machine needs to connect to a computer through its controller box with a parrallel cable (both included). It is not recommended to connect to a notebook through a parrallel port as the power saving features tend to interrupt the data flow. It is also not recommended to connect to a computers with 64 bit versions of Windows due to problems with the Parrallel port driver. These issues are detailed and fully explained on the Software website.

Description:

suitable for PCB, wood, Plexiglass, PVC, Crystal Acrylic, RESIN, Plastic, SEALS, MDF, COMPOSITE, Aluminum material, Copper,

1. This CNC 6040T machine is suitable for industry, Technology Research, Advertising Design,

Arts Creation, Teaching, Student Project and Hobby Purposes.

2. It can work with various materials(metallic & non-metallic), such as: wood, pmma or other plastic,

MDF board, native wood, PVC, Acrylic, wood, composite board plywood. and soft metal. like aluminum,

copper and silver to engrave them into 3D/2D works etc.

3. It can used for engraving: advertising signs, PCB, nameplates, badges, seals, bronzing plate, aluminum alloy, acrylic plates, ABS resin double color plate, PVC foaming board, indentation plates, signs, construction models, instrument panels, wooden products, etc.

4.The mini CNC router Frame is movable. The machine can connect with computer as other external device such as printer, scanner...

5. With the assist of the CNC ROUTER 6040T, your design idea will be real-time display.

CNC Engraving Machine

P

arameters:

X, Y, Z Working Area: 600(Y)*390(X)*120(Z)mm

Outside dimension: 865*680*570mm(L*W*H)

Table size: 770(Y)*490(X)mm

Lathe structure: 6061/6063 Aluminium alloy

Max. Feeding height: ≤100mm

Drive unit:

X axis---1605 Ball Screws

Y axis---1605 Ball Screws

Z axis---1204 Ball Screws

Sliding unit:

X axis---High intensity Chromeplate shaft

Y axis---High intensity Chromeplate shaft

Z axis---High intensity Chromeplate shaft

Stepping motor: 57 two-phase 3A 150N.cm

Spindle motor:

1,Water cooled spindle motor can work longer time than air cooled motor.

2,Water cooled spindle motor has higher stability and better concentricity than air cooled motor.

(tips:

1. The spindle motor must connect with the VFD.

2. It cannot directly connect with the supply voltage (AC220V).

3. Please don’t change the data setting of the VFD if you are not professional technicians, or it might damage the spindle motor.

Outside dimension: 80*188 mm

Material: 304 stainless steel, Copper coil, Pressure cast aluminum pipe water jacket

VOLTS, current, power: AC220v 50hz, 5A,

1.5KW VFD

Spindle motor: 1.5 KW water cooled

Spindle speed: 24000 rpm

Max working frequency: 400Hz

Principal axis collet:ER11collet,Standard configuration :6mm

Nut Model: ER11-A

Cooling: Water-cooling

Speed mode: By adjusting the VFD output voltage and operating frequency

from 0-24000RPM

Lubrication way: Lubricated by high grease

Repeat accuracy: 0.05mm

Spindle precision: radial beat acuities 0.03mm

Carving Instructions: G code / TAB files / nc file / NCC files

Communication interface: through parallel connection with computer

Software environment: Windows XP/win7, 32bits system

Working Speed: 50-1500mm / min

(different material with different speed settings)

Maximum Idle speed: 0-1500mm/min

Friendly reminder:

The engraver will come with software(Free Version

If you followed the installation tips offered by us, it works like full version.)

installation tips:

The software perform better on the 32bites system computer.

Please close the firewall and antivirus software on the computer before DOWNLOADING AND installing the software.(This is very important)

Otherwise, the antivirus will regard the cnc software as virus and stop the installation.

PS:

Please don't update the software when installed, then it will not need the license Numbers.

Control box parameters:

Operating Voltage: AC220V, 50hz

Control unit: Toroidal transformer + PWM power supply module + TB6560stepping motor drive

Computer connection: Parallel port

Command code: G code

Acceptable software:

Protection: Emergency stop button

Feature:

1. The NEW 1.5KW water-cooled VFD is available operating for long time,which can reinforced the processing abilty of the machine and can be used toprocess aluminum alloy and hard wood.

2. water cooling spindle works more stable and durable.

3. High quality accurate ball Screws drive make the engrving more precision.Anti-blackflash,high precision,long life circle.

4. Software Compatability:Type3/ArtCAMParameter

How to Use

1. Assembling and locating the CNC machine on steady desk well.

2. Make sure that your computer has a 25pin parallel port output.

3. Place the contral box in a ventilated dry place where there is no dust, no moisture

4. Connecting the control box with the CNC machine and you computer and make sure the plug will not come off.

5. Correctly connect the machine with the controller. Don't suspended the cable which connect the Spindle motor with axis(X, Y, Z, A). Otherwise, it will damage the driver of the controller.

6. Correctly instal the Spindle motor and the heat pump. The heat pump should be covered completely in the water, then turned on the electric current to check whether the water-cooling system working well.

7. Installing a CNC control software and Drive such as the on your computer.

8. Fllowing our manual or guideline to set uo the software.

9. Before turn on the machine, please check all the cable and water-cooling system to make sure they are working fine.

10. You can enjoy making you dream with using our CNC machine now.

Descrizione:

Adatto per PCB, legno, plexiglass, PVC, cristallo acrilico, resina, plastica, guarnizioni, materiali compositi, di MDF, alluminio, rame,

1. questa macchina CNC 6040T è adatta per industria, tecnologia di ricerca, pubblicità design.

Creazione di arti, insegnamento, studente progetto e hobby fini.

2. può funzionare con vari materiali (metallici e non metallici), come: legno, pmma o l'altra plastica.

Bordo di MDF, legno nativo, PVC, acrilico, legno, compensato bordo composito. e metallo morbido. come l'alluminio,

rame e argento per incidere loro in 3D/2D opere ecc.

3. può essere utilizzato per l'incisione: targhette di segni, PCB, di pubblicità, distintivi, guarnizioni, piastra, per bronzare.

lega di alluminio, lastre acriliche, ABS resina doppio piatto di colore, bordo di schiumatura del PVC, lastre di indentazione, segni.

costruzione modelli, quadri portastrumenti, prodotti in legno, ecc.

4. mini CNC router telaio è mobile. La macchina può connettersi con il computer come

altro dispositivo esterno come stampante, scanner...

5. con l'assist di CNC ROUTER 6040T, vostra idea di design sarà visualizzazione in tempo reale.

Parametri della macchina CNC incisione:

Area di lavoro X, Y, Z: 600 (Y) * 390 (X) * 120 (Z) mm

Dimensione esterna: 865*680*570mm(L*W*H)

Formato della tabella: 770 (Y) * 490 (X) mm

Tornio di struttura: lega di alluminio 6061/6063

Max altezza d'alimentazione: ≤100mm

DRIVE UNIT:

Viti a sfere X Axis--1605

Viti a sfere Y asse-1605

Viti a sfere Z asse-1204

Unità di scorrimento:

Asse-X - albero di Chromeplate ad alta intensità

Albero Y asse--ad alta intensità di Chromeplate

Asse-Z - asse di Chromeplate ad alta intensità

Motore passo-passo: 57 3A 150N.cm a due fasi

Motore mandrino:

(suggerimenti: 1.) Il motore mandrino deve collegarsi con il VFD.

2. non è possibile connettersi direttamente con la tensione di alimentazione (AC220V).

3. si prega di non cambiare l'impostazione di dati di VFD se non siete tecnici professionisti, o potrebbe danneggiare il motore del mandrino.

Dimensione esterna: 80*188 mm

Materiale: 304 serpentina in acciaio inox, rame, pressione cast alluminio tubo acqua giacca

Potenza attuale, volt,: AC220 / 50Hz, 5A, 1.5 KW VFD

Velocità del mandrino: 24000 giri/min

Massima frequenza di lavoro: 400 Hz

Asse principale hebel: ER11collet, configurazione standard: 6mm

Modello di dado: ER11-A

Raffreddamento: Acqua di raffreddamento

Modalità di velocità: regolando il VFD uscita tensione e frequenza da 0-24000 giri/min

Lubrificazione modo: lubrificato con grasso ad alta

Ripetibilità: 0,05 mm

Precisione mandrino: radiale battere le acuità 0,03 mm

Istruzioni di scultura: codice G / TAB file / file nc / file NCC

Interfaccia di comunicazione: attraverso il collegamento in parallelo con il computer

Ambiente software: Windows XP/Win7

Velocità massima: 0-4000 mm/min

Intaglio di velocità: 0-2500 mm/min(different materials differ)

Ricordo amichevole:

L'incisore arriverà con software (versione gratuita

Se avete seguito i suggerimenti di installazione offerti dagli Stati Uniti, funziona come versione completa).

Consigli per l'installazione

:

Il software di eseguire meglio il computer del sistema di 32bites.

Si prega di chiudere il firewall e software antivirus nel computer prima di scaricare ed installare il software. (Questo è molto importante)

In caso contrario, l'antivirus sarà considerare il software cnc come virus e interrompere l'installazione.

PS:

Si prega di non aggiornare il software installato, quindi non avrà bisogno i numeri di licenza.

Parametro di casella di controllo:

Tensione di funzionamento: AC220V

Unità di controllo: PWM + trasformatore toroidale di alimentazione moduli + TB6560stepping motor drive

Connessione computer: porta parallela

Codice comando: codice G

Software di accettabile:

Protezione: Pulsante di arresto d'emergenza

Caratteristica:

1. il nuovo 1.5 KW è disponibile di funzionamento per lungo tempo l'elaborazione di rinforzo VFD raffreddato ad acqua, che può

abilty della macchina e può essere usato aprocesso in lega di alluminio e legno duro.

2. acqua di raffreddamento mandrino funziona più stabile e durevole.

3. alta qualità accurata viti a ricircolo rendono il engrving più precisione. Anti-Flash nero, alta precisione, lungo il cerchio della vita.

4. software compatibilità: Type3/ArtCAMParameter

Come usare:

1. assemblaggio e l'individuazione della macchina CNC in costante reception bene.

2. Assicurarsi che che il computer disponga di un'uscita di porta parallela 25pin.

3. Posizionare la casella di contral in luogo ventilato e asciutto dove non c'è nessuna polvere e umidità non

4. Collegare la casella di controllo con la macchina CNC e il computer

e assicurarsi che la spina non staccarsi.

5. Collegare la macchina con il controller. Fare non sospeso

il cavo che collega il motore mandrino con asse (X, Y, Z, A). In caso contrario, potrebbe danneggiare

il driver del controller.

6 installare correttamente il motore mandrino e la pompa di calore. La pompa di calore

dovrebbe essere coperto completamente l'acqua, poi acceso l'elettrico corrente per controllare se

il sistema di raffreddamento funziona bene.

7 installare un CNC software di controllo e azionamento come il on il computer.

8 Fllowing nostro manuale o Guida di riferimento per impostare uo il software.

9 prima di accendere la macchina, si prega di controllare tutti i cavi e acqua

raffreddamento di sistema per assicurarsi che si sta lavorando bene.

10 che si può godere facendo sognate con usando la nostra macchina CNC ora.

Applicable User&Skills:

1. Advertising&Design staff

2. PCB Engineer

3. Woodwork fans

4. Model fans

5. User should better have electronics background

6. DIY ability to repair

Highlights of water cooling system :

It can cool the spindle and protect the machine

Avoid the spindle burn out

Can engrave the high hardness or metal

It can improve the efficiency and accuracy of the machine.

Payment

Delivery details

Feedback

Return policy

Contact us

Payment

We accept PayPal and bank transfer.

All payments must be made within 7 days after the auction ends. Non-paying bidders will be reported to eBay. Please don't buy an item if you can't/won't pay for it. We accept Credit Cards via PayPal.

Delivery details

We have the warehouse at the UK ,the item is shipping from Germany warehouse within 1-2 is business day after payment is made .

4-9 working days to:

UK by DHL

5-7 working days to:

France ,Germany ,spain ,Italy

6-10 working days to:

Other countries

Feedback

We maintain high standards of excellence and strive for hundred percent customer satisfaction. Feedback is very important to us. We hope that you contact us immediately before you give neutral or negative feedback, so that we can address your concerns. It is impossible to address issues if we do not know about them!

Return policy

Please keep the original box or packaging within 15days since item received. Returned item must come with original box or packaging.

Your satisfaction is our ultimate goal. We work hard to earn your trust and future business. Our certified technicians have tested each item before shipping. The unit comes with 1 year limited warranty on all manufacturing defects.

a) If you receive a defective item, you may return it or ask for a discount. Please contact us within 14 days after you receive the package.

b) What you returned must be intact and in its original packaging as re? u. Customer is responsible for shipping costs of the returned item.

c) We will cover the cost of shipping back t with the shipping rate indicated in the registration page. We will send you a new unit or refund the full payment you paid.

Thank you.

Contact us

Business Hour: Monday To Friday: 8:30 AM to 5:00 PM (Beijing China time)

Due to time zones, our reply to your questions may not be immediately. But within above working time, we will reply your email within 24 hours. If it's non-workdays, please kindly be patient and wait till Monday.

Please contact us with ebay message.

Please feel free to contact us if you have any questions.

Feedback

On Jul-07-21 at 01:57:14 PDT, seller added the following information: